Comprehensive Machining Solutions Under One Roof

Barnes Precision Machine operates a fully integrated manufacturing facility with advanced CNC capabilities, quality systems, and regulatory compliance to support the most demanding applications.

CNC Milling

- CNC Milling 3 & 4 axis

- CNC Lathe Chuck 8″ dia max

- CNC Lathe Chuck 8″ dia max

- CNC Lathe Chuck 8″ dia max

- Materials: aluminum, steel, stainless, titanium, exotic alloys

CNC Turning

- Multi-axis turning centers

- Live tooling and sub-spindle capabilities

- Bar capacity to 3″ diameter

- Chuck work to 12″ diameter

- Complex geometries and tight tolerances

Swiss Machining

- CNC Swiss-style sliding headstock lathes

- Lights-out production capabilities

- Bar stock to 1.25″ diameter

- Simultaneous front and back operations

- High-volume precision components

Tool Room Services

- Custom fixturing and tooling design

- Prototype development

- Small-batch production

- Engineering support and DFM consultation

Proven Expertise Across Critical Industries

Our 32+ years of experience spans multiple high-precision industries, each with unique requirements and exacting standards.

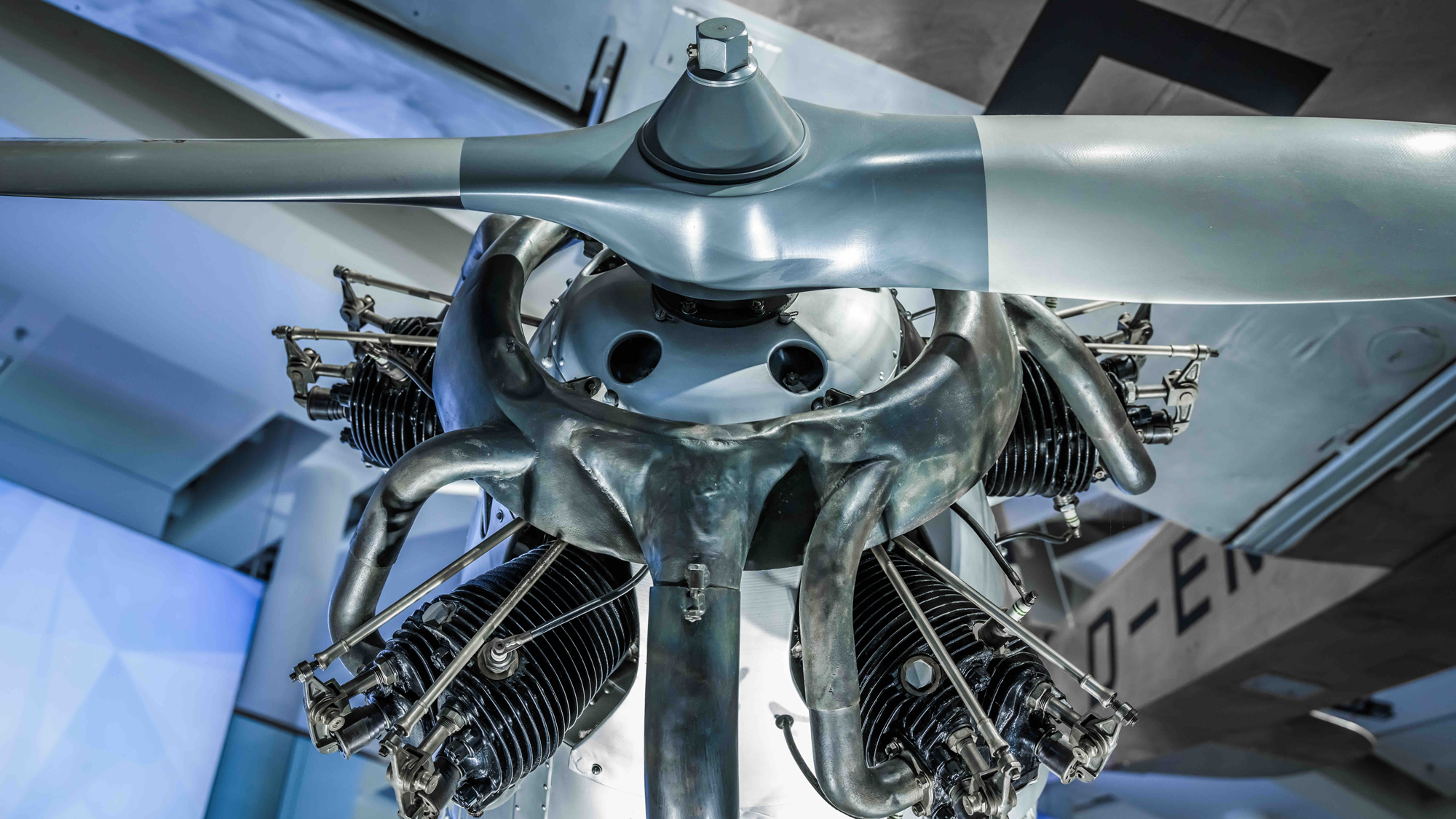

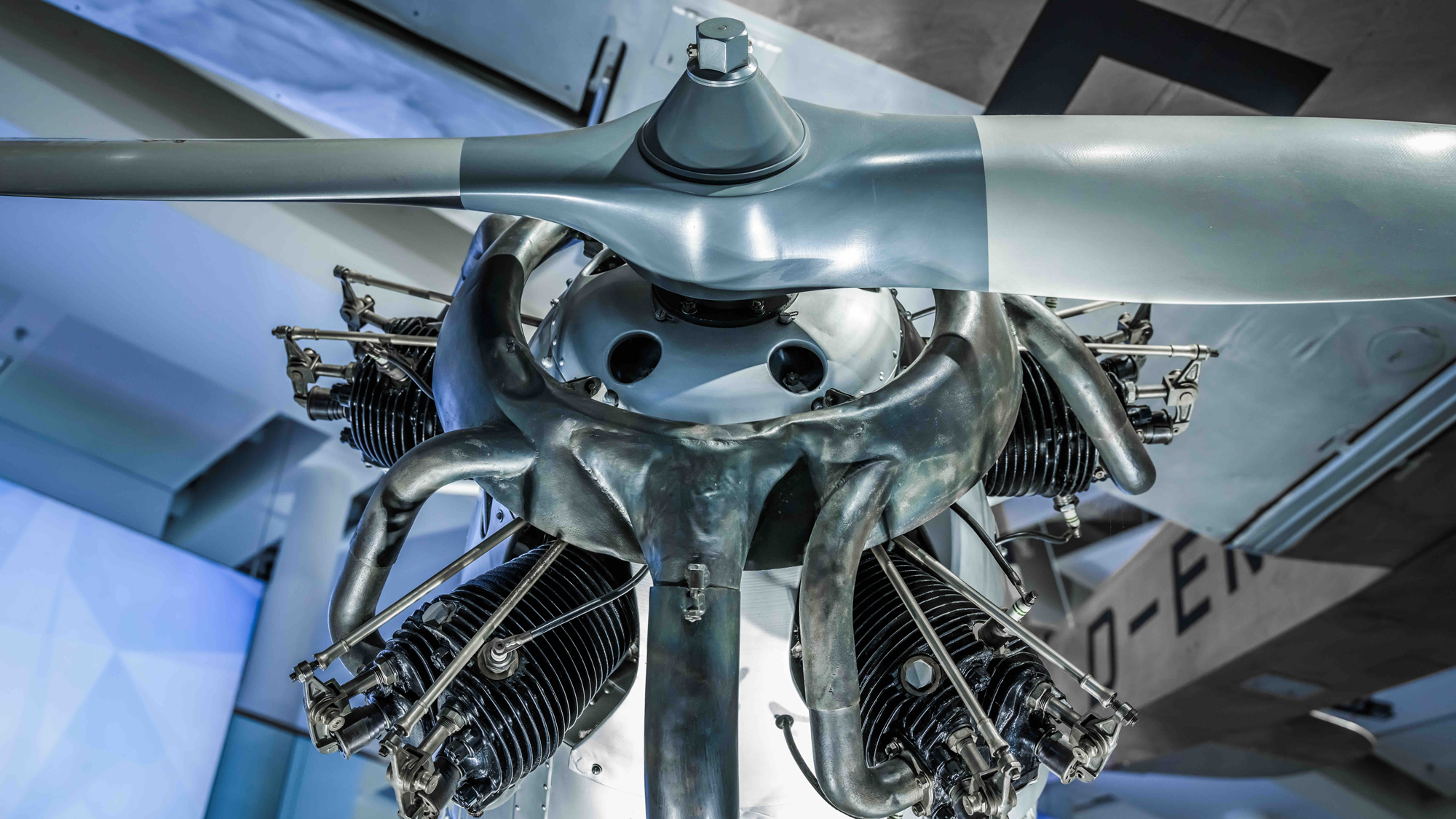

Aerospace & Defense

For over two decades, Barnes has manufactured critical components for UAV systems, guided munitions, and armor applications where failure is not an option. Our AS9100 certification and ITAR compliance enable us to support prime contractors and government agencies with the highest security and quality requirements.

Medical Technology

Barnes serves medical device manufacturers and diagnostic equipment companies with precision components that meet the exacting standards of healthcare applications. Our ISO 9001 foundation provides the quality framework for regulatory compliance while our small-batch capabilities support both prototype development and specialized production runs.

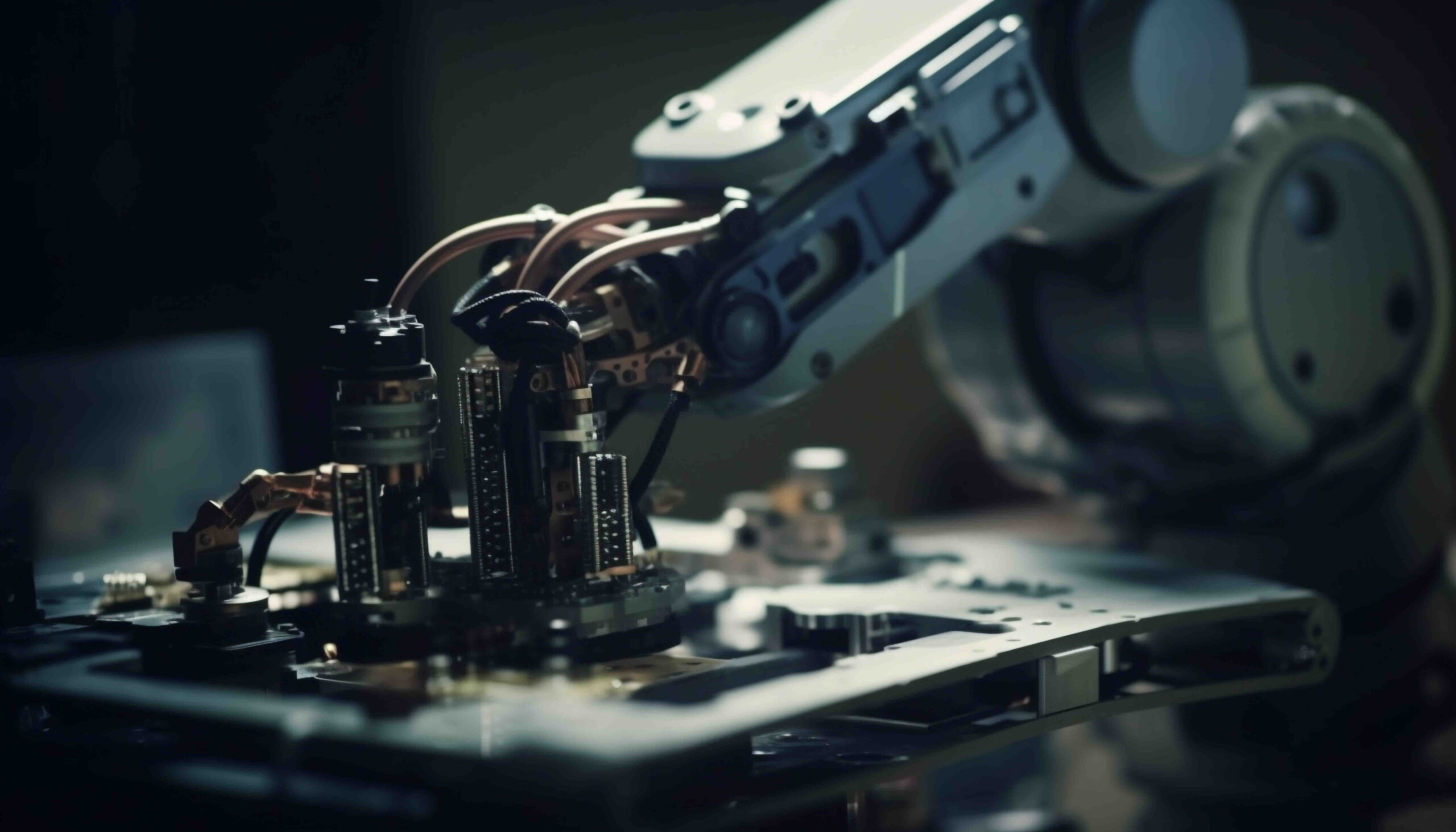

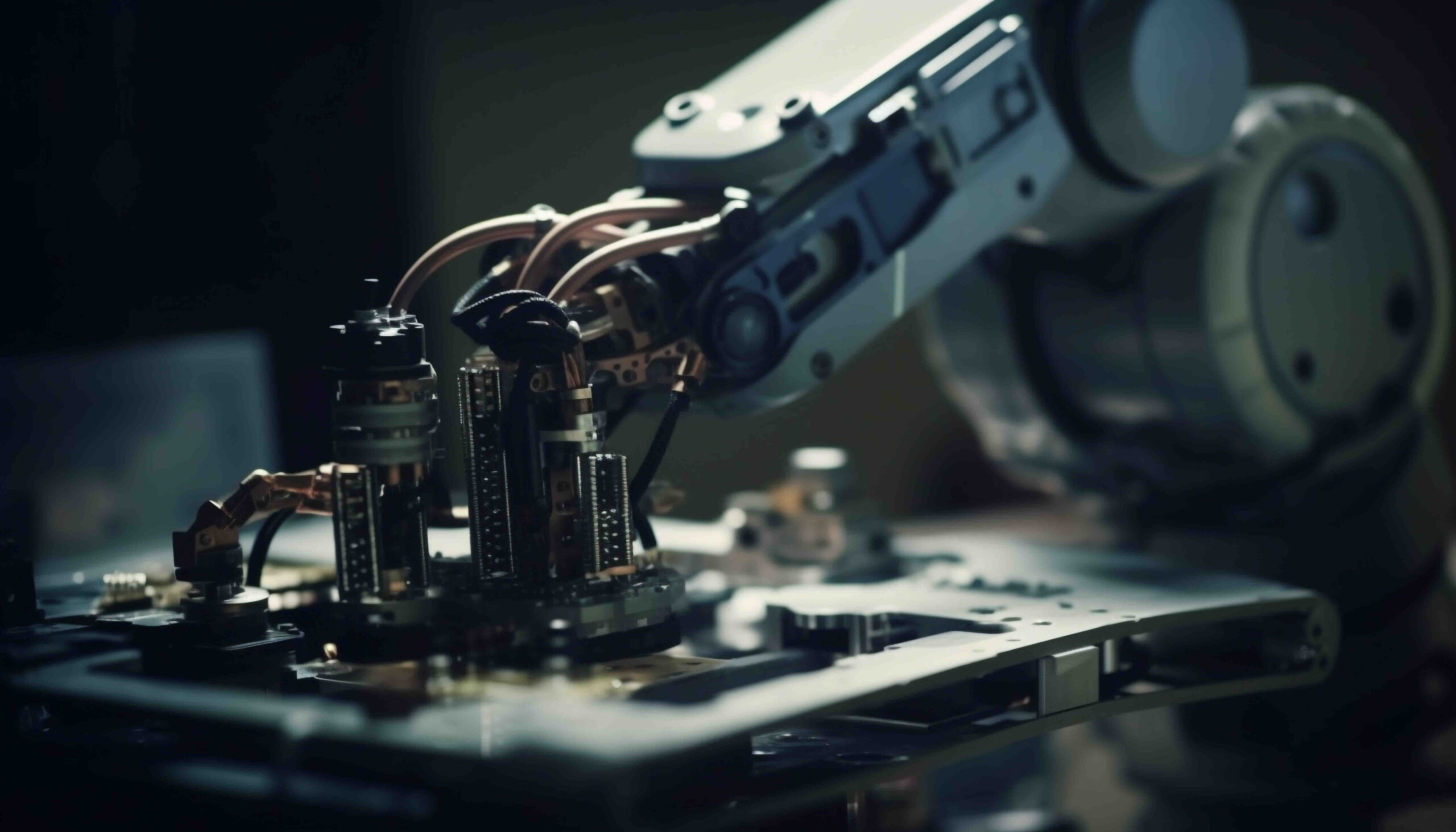

Automation & Robotics

Our automation industry clients include ATI/Novanta and other leading robotics companies who rely on Barnes for precision tooling and positioning components. We understand the tight tolerance requirements and surface finish specifications that enable reliable automated systems.

Firearms OEM

As the OEM partner to 15+ firearms manufacturers, Barnes brings three decades of precision machining expertise to military, law enforcement, and commercial markets. Our Type 7 FFL and proprietary finishing processes like Nickel Boron coatings have established us as an industry leader in high-performance firearm components.

Certified Excellence in Every Component

Quality management is fundamental to our operations, with certified systems that meet the most stringent industry requirements.

AS9100 Rev D

Aerospace quality management system certification ensuring consistent processes and continuous improvement for aviation, space, and defense applications.

ISO 9001:2015

International quality management standard demonstrating our commitment to customer satisfaction and regulatory compliance.

Type 7 FFL

Federal firearms manufacturer license enabling legal manufacturing, assembly, and distribution of firearms and components.

ITAR Registration

International Traffic in Arms Regulations compliance for defense-related manufacturing and export control.

Ready to Start Your Project?

Our engineering team is ready to review your requirements and provide a detailed quotation for your precision machining needs. Simply provide your project details and technical documentation using the form below, and we’ll respond with a comprehensive quote within 24-48 hours for standard projects.

What We Need

To provide an accurate quote, please include technical documentation, material specifications, quantity requirements, and delivery timeline. Complete information helps us deliver the most competitive pricing and realistic lead times for your project.

- CAD files (STEP, IGES, or native formats) and engineering drawings

- Material specifications and special process requirements

- Quantity requirements and delivery schedule expectations

- Quality certifications and documentation needs