32 Years of Precision, Innovation, and Trust

From racing engines to aerospace to AR parts — we’ve been solving machining challenges since 1992.

Built on Performance.

Proven by Results.

In 1992 Andrew Barnes founded BPM, and earned their reputation early on serving local automation, robotics customers along with being production supplier to Carolina Archery Products, and the well-known Whisker biscuit Arrow Rest. This grew BPM from 3 CNC Machines to 21 CNC Machines in a very short time frame. While serving motorsports industry customers, BPM competed in Short Track Racing with a Late Model Super Truck /ASA Pro Truck with BPM #33 at various short tracks in NC.

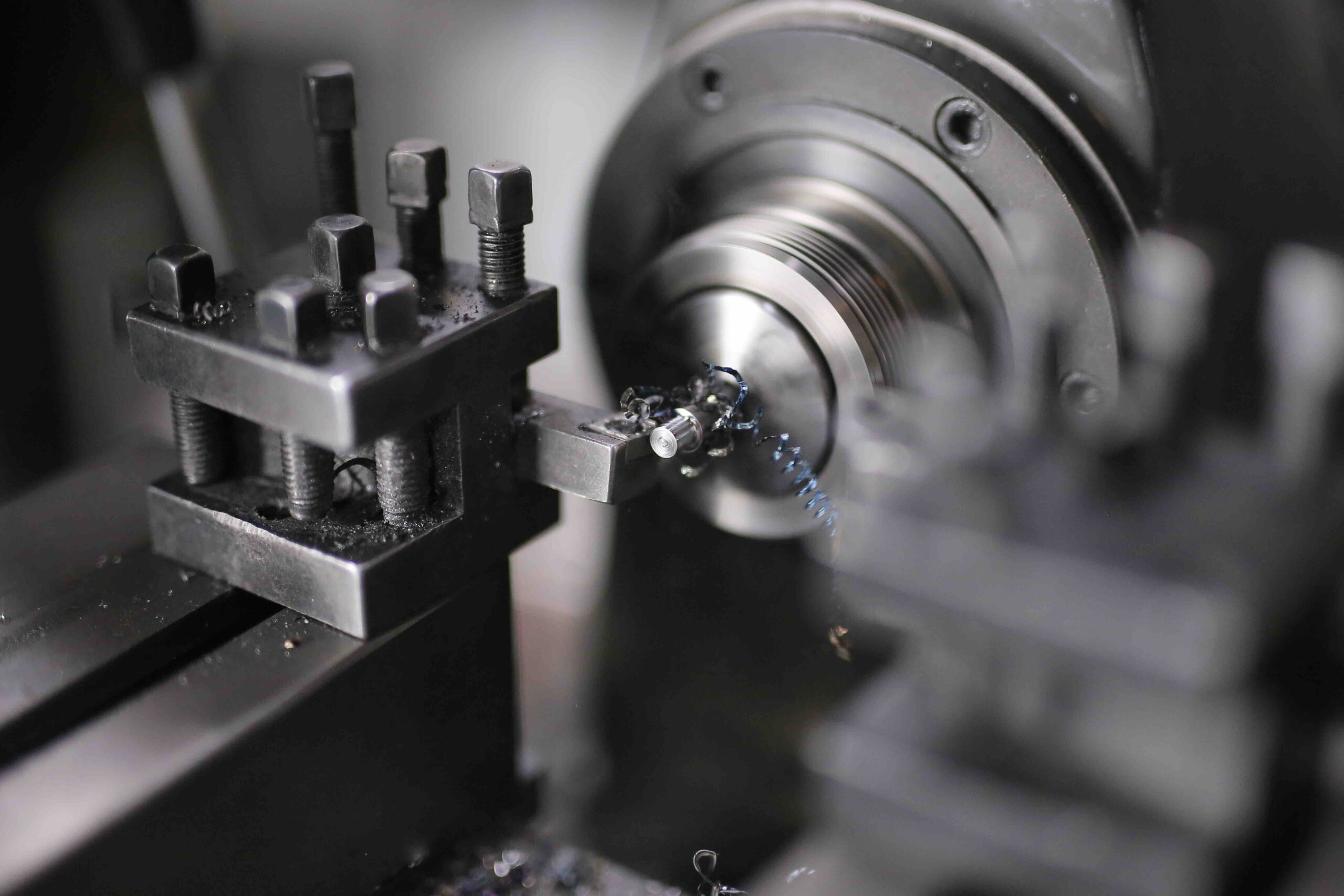

That commitment to precision, and hard work -enabled BPM to eventually acquire 32 CNC Machines and service various industries with their Quality CNC Machining capabilities to include CNC Swiss Lathe Machining needs.

Key Milestones:

1992 – established by Andrew Barnes ,purchased first manual mill and manual lathe.

1995 – 3 axis CNC Knee Mill

1996 – 2 axis CNC lathe ,w bar-feeder

1998 – 3 axis Vertical Machining Center

1999 – 3 axis Haas VMC

2000 – CNC Swiss Lathe

2004 – moved into new larger facility

2005 – expanded into aerospace /defense/firearms industries

2008 – developed /established patent for PSFFRS (Picatinny Spec Free Float Rail System)

2009 – FFL/Type7 manufacturers license

2010 – first in industry to ship rifles with NiB BCG as standard.

2012 – Increase in CNC Swiss services offered with 4 additional machines purchased , received AS9100/ISO9001 certifications

2014-2025 – continuing to serve as a reputable NC Precision CNC Machining Service, with more emphasis on Local Automation/Robotics/Automotive industry markets.

Pioneering Better Manufacturing

Barnes Precision Machine has always been driven by innovation, not imitation. We don’t follow industry trends — we create them.

Our Industry-First Achievements:

Nickel Boron Coating Leadership

BPM was first company to ship NiB BCG’s as standard in their rifles. Today NiB is a standard high quality option in many companies products.

Picatinny Rail Innovation

Barnes pioneered the development of Picatinny-spec free-float rail systems specifically engineered for laser and guided-munitions alignment. Our rails became the benchmark for precision weapon systems, adopted by military contractors and civilian builders alike.

Black Nitride Process Mastery

We were among the first manufacturers to perfect Black Nitride finishing for firearms components, offering superior hardness and wear resistance compared to traditional treatments. First company to offer black Nitride gas tubes for increased life expectancy /wear protection.

Lights-Out Production Excellence

Our investment in Swiss-style sliding headstock lathes and automated production systems allows us to run complex parts unattended, delivering consistent quality at competitive pricing.

Built Here. Trusted Everywhere.

Every Barnes Precision Machine component is manufactured in-house at our 15,000 square foot facility in Apex, North Carolina. We maintain complete control over our domestic supply chain, from raw materials to finished products.

Barnes Precision Machine has maintained the highest industry certifications to serve our customers from various industries.